Lab Center

The importance of agricultural management starts with related researches such as the research and development of plants and animals, examinations such as soil, micro-organism, production factors and agricultural product accreditation.

The ASEAN’s central labs will consist of several labs with different sizes all over the region. This is to set the highest standards in the research and development, examination, analysis and accreditation of the agricultural processes ranging from soil, production factors, plant diseases and pests to agricultural products and manufacturing.

Super SCADA Information Center

The Supervisory Control And Data Acquisition System (SCADA) is a “central control system”. It collects information from field instruments or controllers from various areas of the agro industry and transfers all the data to the central site for data analysis and processing by the computers. This will be useful for data collection and application when needed, and it can be centrally controlled and commanded.

All agricultural implementations will be monitored, recorded, followed up and observed for any undesirable agricultural results. This enables prompt support at the farm as well as remote control and command for the full-fledged presentation from the production sites directly to the customers.

Plant Tissue Culture Center

The plant tissue culture is taking some part of plants either organs or tissue to grow in scientific fertilizer consisting of minerals, sugar, vitamins and growth control agents under micro-organism-free and environmentally controlled environments: temperature, light and moisture. The plant parts can grow in different forms either organ development which creates groups of cells called callus that makes young plants called embryo. In the end, the plant organs are forced to make new plants with perfect rooting ready for planting in the soil. Plants from tissue culture will have completely the same characteristics as their mother plants. This is one of plant propagation, keeping and conserving techniques. Plant calluses are kept at -196 degree Celsius in liquid nitrogen. This technique can keep plant characteristics for many years without mutation. Or it will be useful for collecting seedlings in limited space by keeping them in small bottles and they will grow slowly.

In addition, tissue culture is useful for conveniently exchanging seedlings overseas. Plants kept in the bottles are free from micro-organism and fungi that can be harmful to plants. Especially, herb tissue culture in the form of hanging cells helps produce agents that can be used as medicines or pesticide. It is also extremely beneficial in improving the plants to be more tolerant against plant diseases and harmful pests. Or it can be more productive with the use of young small seedlings. In addition, there are plant’s pollen anther and pollen grain culture as well as the use of chemical and radioactive technique for developing and producing new plant breeds.

The plant tissue culture has been developed for plant breed propagation extensively. There are commercial tissue culture widely in Europe, the United States, Canada and Japan. Growth in the future is expected to be even more in terms of most industrially appropriate techniques, cost reduction and commercial viability. Once the technology reaches commercial and industrial level, it enables the development of new plants and plant-based products for future application in a larger scale.

Objectives

1. To build the world’s largest, most advanced and modernized plant tissue culture center

2. To become the best plant research and development center

3. To collect and conserve plants which are indigenous, rare and endangered of extinction, best and desirable characteristics or exchangeable overseas

4. To be the center for DNA cloning

5. To be the educational center on plant bio-chemical and physiological study

6. To be the center for plant cryopreservation

7. To be the educational center and production base on resistant plants and tolerant plant

8. To become one of the world’s major commercial tissue culture seedling producers

Goals

Construction of a large-sized plant tissue culture center in

@ Ayuthaya Province

@ Yala Province

@ Chiangmai

@ Nakhon Rajsima

@ Petchabun

@ Phrae

@ Sakon Nakhon

@ Chonburi

@ Chumphon

@ Nakhon Sri Thammarat

Applications of Plant Tissue Culture

1. Ability to produce a large number of seedlings in a short period of time

2. Ability to produce seedlings with the same characteristics of mother plants

3. Ability to produce a big number of plants with the same size

4. Ability to produce plants without plant diseases

5. Ability to keep and conserve specific plants: indigenous, rare and endangered of extinction, best and desirable characteristics or exchangeable overseas

6. Ability to improve plant seedlings in order to produce resistant plants. The plants creates resistance in the plants by growing in different conditions, for example, plant disease resistant, pest resistant or herbicide resistant. Or, plant tissue culture can produce a tolerance plant from different growing and environmental conditions, for example, the selection of salt tolerant plant from growing the plant by providing. tissue growing food mixed with salt and the selection of acid tolerant plant by providing the tissue with acid food and the selection of heat tolerant plant by growing the plant in high temperature condition

7. Ability to produce plant – based. medicines or chemicals and produce secondary metabolite (synthesizing desirable agents in large amount)

8. Ability to distill plant-based agent for various benefits

9. Ability to produce both resistant and tolerant plants such as salt tolerant or acid tolerant, hot or cold temperature tolerant, pesticide tolerant, plant disease tolerant and toxic – related tolerant caused by fungi, bacteria and virus

10. Ability to produce protoplasts (Plant protoplasts are naked plant cells. They only have cell membranes covering the inner cell component)

11. Ability to produce plants with chromosome of polyploids (Chromosome is the habitat of DNA and gene that control and transfer the data of hereditary characteristics of living things)

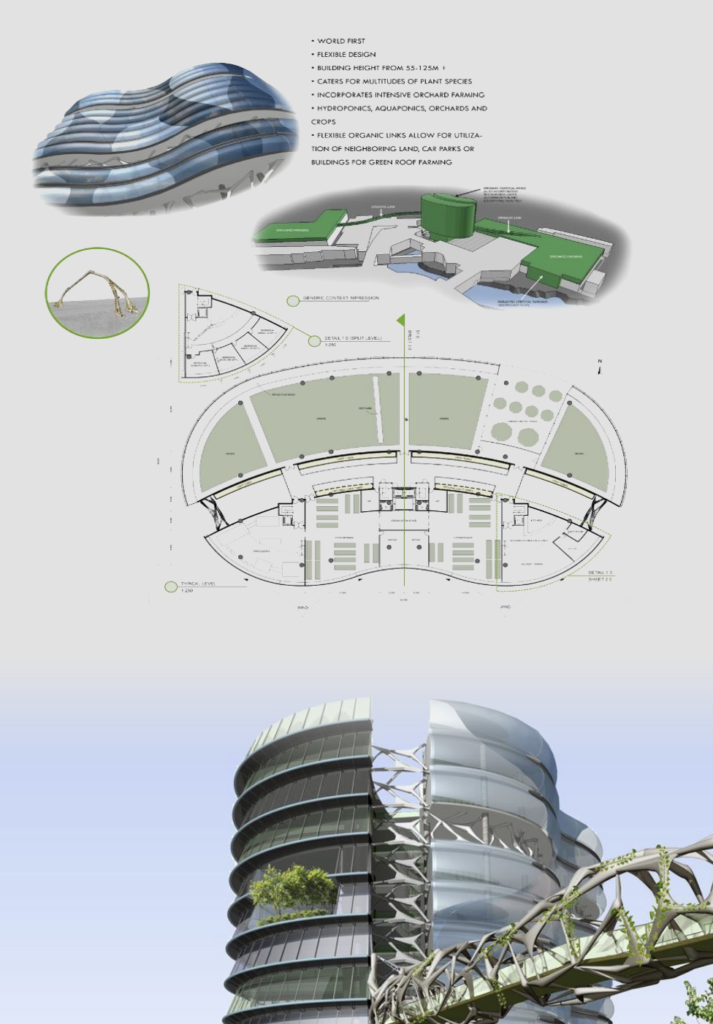

The Concept of Constructing the World’s Largest and Most Modernized Plant Tissue Culture

In designing the world’s largest and most modernized plant tissue culture center, best technological know-how of the time being will be integrated with innovations, research, experimentation and prototypes from inventors, organizations and institutions in order to develop to reach the desirable objectives

Therefore, this plant tissue culture center will be designed and built for the first time of the world that needs substantial investment fund and the collaboration of best experts of each field.

In building this world’s plant tissue culture center, there are detailed studies on construction format and the Implementations of various world’s major plant tissue culture centers so as to design the world’s most complete plant tissue culture. Only best equipment, tools and materials will be procured for the construction and Implementations to the center in order to fulfill the objectives.

Main Systems Available in the World’s Plant Tissue Culture Center

1. Intelligent Building and Clean Room.

2. Environment Control

3. Pneumatic Tube System

The pneumatic tube system delivers documents and materials by the wind force through the tubes that are equipped as networks linking the sending and receiving points using shuttles and the media. There are different sizes of the media appropriately according to different work types. The system is suitable for the delivery of small items that need urgency, thus helping to save time and provide safe delivery.

How Pneumatic Tube System Works

The pneumatic tube system requires wind force generator as the prime mover in blowing or sucking in the tubing system with a diverter as an assisting tool in sending the carrier to different directions in the system without the limit on distance or height. An operator only inserts or puts items or document into a specially designed tubal container called carrier and put the carrier into a sending tube at the sending station. After entering the receiving station’s code, the system then delivers items via the tube fast and completely. Also, with the system’s central control, the items delivered via the tub reach the receiver correctly and safely.

4. Robotics System and Servo Systems

5. Monitoring System

– Closed-circuit Television (CCTV)

– Sensors for Temperature and Moisture

– Sensors for Light Measurement

– Sensors for Plant Tissue Growth

– Sensors for Other Inspection, Examination and Surveillance

– Equipment for Data Collection and Analysis

6. Supervisory Control And Data Acquisition System (SCADA)

The Supervisory Control And Data Acquisition System (SCADA) is a “central control system” in collecting information from field instruments or controllers from various areas within the plant tissue culture center. Varied data is transferred to the central site before being processed and analyzed by the computers. Then the desirable information will be kept or applied as needed.

7. Artificial Intelligence System

Artificial Intelligence (AI) is how a non-living thing is equipped with artificial intelligence tools in order for the central command within the center. This includes air conditioning, moisture, electricity and clean water systems.

Plant Research and Development Center

The plant research and development center is responsible for collecting various plant genomes from all parts of the country. This is to conserve plant seedlings either heirloom or hybrid. This includes the study of plant breed characteristics, recording data of the plant, propagating and keeping in the form of seeds and tissue cells in controlled temperature and moisture. Also, there are planting plots of various plants as a learning station as well as further research and development of the plants. There is an evaluation for plants’ desirable characteristics or economic viability for best utilization. There are plant selection and seedling improvement beneficial for both further study and farming application. There are research and study on appropriate and healthy plant production. The technological research and development on high quality plant seed production are also available.

Animal Breed Research and Development Center

The animal breed research and development center is responsible for collecting animal breed genomes from all parts of the country. This is to conserve animal breeds both of indigenous and hybrid. This includes the study of animal breed characteristics, recording data of the breed, reproduction and keeping the breed in the form of seminal fluid, egg and embryo in appropriately controlled temperature and moisture. Breeding stations with breeding parents are set up for learning purposes and the research and development of the animal breeding parents. There is an evaluation for good characteristics and economic viability of breeding genomes for most utilization. There are animal breed selection and improvement for the purposes of both further study as well as application by agriculturalists. There are research and study on appropriate and healthy animal production. The technological research and development on high quality animal breed production are also available.

Fertilizer Center

The impacts caused by the Green Revolution in 1960 when technology was first applied in agricultural practice that made high yields with the use of chemical substances and machineries have created changes in other aspects such as socio-economic situations, politics, cultures, health and global ecology.

The strong point of the Green Revolution is bringing scientific advancement and technology to significantly increase agricultural yields such as the yield of rice production. However, the weak point is the neglecting of negative social and environmental impacts, especially the negative impacts on ecological systems that are highly complex and sensitive.

The Green Revolution eventually has become the mainstream policy of every country where the majority of people especially farmers are persuaded to accept the farming technique through educational system and mass media.

Fertilizer Center

The Green Revolution has pushed Thailand to “new agricultural practice”. Chemical substances have been applied in agriculture in a long, continued fashion and have caused the following negative impacts.

1. Environmental Impacts

Ecological systems have been destroyed with environmental problems and deteriorating natural resources. Some physical impact is soil erosion, thus makes the soil infertile, lacking of effective microorganism. Other problems are environmental toxicity and the spread of disease and harmful pests

The use of chemical fertilizer in big amount and continued fashion has led to the deterioration of soil structure. The soil is infertile because applying chemical fertilizer is not nurturing the soil but putting plant’s food without putting organic matters. It by contrast speeds up the decomposing of organic matters thus making poorer soil structure. The soil becomes hard and compact not holding water during the dry season. The application of chemical pesticide causes toxic contamination in the environment. Only 25% of each chemical pesticide spray is successful while the remaining 75% spreads into the soil, water and air. Very importantly, chemical pesticide spray not only kills pests, but destroys beneficial insects and micro-organism. It also destroys the ecological balance which in turns causing the spread of diseases and pests even worse.

2. Economic Impacts

The “new agricultural practice” depends heavily on outside factors in order to have high yields. But it does not necessarily mean that those agriculturalists are successful. On the other hand, most agriculturalists taking the new agricultural practice are in debt with economic loss due to high production cost and low prices.

In Thailand, the new agricultural practice has pushed agriculturalist to be under the domination of agro business firms. They depend on production factors and technology supplied by the firms such as seeds, fertilizer and chemical pesticide. The large agro firms are like being monopoly in agricultural production and trading, sweeping much more of the benefits from total agriculture than general agriculturalists.

3. Impacts on Physical Health of Agriculturalists and Consumers

Application of chemical pesticide not only impacts the environment but also harms agriculturalists’ health as well as causing toxic contamination of agricultural products. Continued uses of agricultural chemicals results in agricultural products contaminated with toxic substances, causing poor health of consumers.

Results from the examinations of agricultural products’ toxic contamination show that some products contain so high toxic contamination that the fail the standard criteria, thus affecting Thailand’s export of agricultural goods. Thai consumers have suffered from accumulated agricultural product toxic and get sickness from allergies, stress and cancer. Statistics show that more and more Thai people have suffered from cancer each year.

4. Impacts on People’s Way of Life and Local Wisdom

The “new agricultural practice” has changed the way of life of Thai agriculturalists. It has ruined the subsistent agriculture and social systems in farming communities. It affects the way of thinking regarding local wisdoms which are neglected. They look at the wisdom as being obsolete, not scientific and inefficient. They forget that those useful wisdoms have been accumulated and transferred from older to the following generations.

This way of thinking was even more active when the “Green Revolution” was newly started. The know-how and agricultural development direction were put together in government’s agricultural offices and large agro businesses. The agricultural development and agriculturalists’ problems have been taken care of by experts from the government agencies or agro business firms. They have solely changed the way of thinking and agricultural practice of the agriculturists. If it is a foul or incorrect know-how, only the agriculturists are responsible for the losses

High Quality Natural Fertiliser with

Bio-technological Innovations

The natural fertilizer program integrates new bio-technological innovation, humus and 100% natural organic matters to make high quality natural fertilizer . The fertilizer helps turn deteriorated soil lacking of nutrients and micro-organisms to be fertile full of natural nutrients and micro-organism. This brings back balanced soil and ecological systems resulting in strong plant with ability to resist diseases and pests and tolerate unfriendly changing climate. After all, healthy and clean agricultural products including vegetables and fruits will be made available.

Objectives

1. To build the country’s most modernized, largest natural fertilizer with the highest production capacity

2. To make it the most complete center for the research and development of natural fertilizer

3. To make it plant food sources to support the program’s agriculturalists

4. To bring the country’s natural resources (humus) to develop and make the optimal use

5. To promote the good health of both agriculturalists and consumers from the reduction and cancelation of agricultural chemical application

6. To make vegetables and fruits clean and safe with full of nutrients and genuine traits

Goals

1. Construction of Natural Fertilizer Center in

– Ayuthaya 1 Center

– Yala 1 Center

– Chiangmai 1 Center

– Nakon Rajsima 1 Center

– Sakon Nakhon 1 Center

– Payao 1 Center

2. Establishment of Humus Mining Center in

Nakon Rajsima. 1 Center

3. Natural Fertilizer with Production Capability of 40,000,000 sacks per year

4. Pelleted bio-fertilizer with Production Capability of 40,000,000 sacks per year

5. Liquid bio-fertilizer with Production Capability of 40,000,000 liters per year

Project Details

a mine in Payao Province. Statistics from a geological survey shows that there is approximately 6,800,000 metric tons of humus and 12,000,000 metric tons of silicon sand

Five natural fertilizer centers will support 14,000,000 farming families all over the country. The locations of the 5 natural fertilizer centers are namely Phetchabun, Yala, Chiangmai, Nakhon Rajsima and Ayuthaya. The humus and silicon mine and the dress up facility are located in Payao Province. The natural fertilizer’s main office is located in Ayuthaya Province.

Plan for Setting up Natural Fertilizer Centers

1. Main Office and Natural Fertilizer Center in Ayuthaya Province

2. Natural Fertilizer Center in Yala Province

3. Natural Fertilizer Center in Chiangmai Province

4. Natural Fertilizer Center in Nakhon Rajsima Province

5. Natural Fertilizer Center in Sakon Nakhon Province

6. Humus and Silicon Mine in Payao Province

Animal Feed Center

Animal husbandry nowadays has been transformed from basic household animal raising to commercial activity with convenient manufactured feed and profitable outcome. Therefore, the demand for the ready-made feed is on the rise resulting in the big expansion of animal feed industries in the country. Most of the feeding processes depend on raw materials available in the country such as rice bran, broken rice, maize, sorghum, cassava, fish meal and soy bean meals, for example. Some vitamins and minerals may also be added to the animal feed. Thailand produces a total of 3,000,000 tons of animal feed each year most of which is used up in the country.

The Good Manufacturing Practice (GMP), which is the standard benchmark focusing on preventing and getting rid of risks on food toxic contamination or poisonous food that is harmful to consumers, must be in place. It is the basic step of quality assurance system before moving up to higher levels. There are two major types of animal feeds: raw material facility and ready-made feed factory

Our animal feed center is for the research and development of advanced bio-technology namely probiotics and prebiotics in order to replace antibiotics. Both of them are highly safe in suppressing diseases, increasing immunity, increasing the ability of digestion and osmosis of nutrients. It results in growth rate, feed exchange rate, quality and yield as well as the reduction of cholesterol. Probiotics mechanism takes part in the process of balancing the level of intestine micro-organism by promoting the growth of effective micro-organism while suppressing pathogenic micro-organism. This is contrary to antibiotics which suppress the growth of both types of micro-organism. The way probiotics work shows the importance of probiotics’ survival in the process of animal feed pellet production which is the type of feed that provide best benefit for animal growth. The pellet animal feed requires high temperature in the process of steam conditioning and pelleting.

The animal husbandry industry in Thailand nowadays is operated with high genomic potential in the farm. There is a good health protection system with the use of antibiotic drugs and chemical agents added into the feed meal so that best animal yields can be achieved. However, it results in the toxic contamination in meat and animal-based products. Consumers, therefore, call for the reduction of antibiotics and chemical agent uses. There is also tariff by overseas markets on Thai meat products such as chicken and prawn to be chemical and antibiotic free. Therefore, there is an effort to find ways for animal to grow best as usual without toxic contamination in meat products. One of the proven ways is the application of natural animal products and bio-technology. The bio-technology helps in animal breed improvement and accelerates animal growth replacing the antibiotics. It helps increase the digestion of feed nutrients so that it reduces the amount of undigested feed nutrients and also reduces environmental contamination.

With the rapid economic growth of Thailand, industry sector is expanding accordingly. Agriculture and animal husbandry, therefore need to follow suit. To develop the animal husbandry by promoting export is one of the ways to help improve the agricultural sector. Thus, animal feed is an important factor for the development of the animal husbandry to be more competitive in the world market with the cost reduction. Animal feed accounts for 60-70% of the total production costs. The animal feeding industry must be developed on the production process to achieve the quality standard. In addition, to reach international standards,

Plant Production under Controlled Environment Center and Animal Production under Controlled Environment Center

The plan of building “agricultural produc-tion under controlled environment center” is designed with the concept that all Thai people consume high quality foods as medicinal foods free from toxic contam-ination or pathogenic agents.

The “agricultural production under controlled environment center” brings innovations and technology of the future to operate and manage virtual natural environment in controlled space. This makes it possible for fixing and controlling agricultural production as desired.

Agricultural Product Management Center

Fresh Raw Materials

This unit collects agricultural products from farming members and brings them to either the local marketing center of each province (77 centers) or to the more diversified manufacturing center in an agro industry town (10 agro industry towns nation-wide).

Manufacturing

– Activated Charcoal and Wood Pellet Plant

– Rice mill

– Pelleted and Powdered Bio Fertilizer Plant

– Liquid Bio Fertilizer Plant

– Agricultural Manufacturing

organic sugar mill

(Organic Sugar Cane)

Organic Sugar Mill under the umbrella of New Era Sky United Empire Co., Ltd. ( NSUE )

Organic Sugar Mill under the umbrella of New Era Sky United Empire Co., Ltd. (NSUE) established in 2021 which is located at Tambol Sammor, Aumphur Sammor, Udon Thani Province is the starting the organic sugar business of NSUE with its mission to become one of the big producers and suppliers of raw sugar, refined sugar, organic syrup, and unrefined sugar to supply to local markets and for exports with capacity of 500,000 Tons of raw sugar canes ( Five Hundred Thousand Tons) or 60,000,000 Tons of raw sugar canes ( Sixty Million Tons ) per Annum.

In general, usually 1 Ton of raw sugar cane can produce 100-120 Kilogram of refined sugar. The proceed will produce the bagasse about 250-300 Kilogram with 50% moisture, and about 50-60 Kilogram of Mollas, and sugar sludge about 30-40 Kilograms.

With wide range of products including raw sugar, refined sugar, unrefined sugar, liquid glucose, modified sugar and etc. under the brand “NSUE”. Organic materials will be used from the beginning of the sugar plantation using best soil additive biotechnology. NSUE will also promote and support the use of all organic materials, especially all types of fertilizer, to all the partners and farmers. All the production process will be at the world standard and safe for all consumers.

NSUE concerns the most with health of the farmers, consumers, animals and surrounding environments (Health and Environment Concern). NSUE concentrates on systematic sugar plantation, therefore, we useGlobal Positioning System (GPS) and Geographic Information System (GIS) to manage and improve the quality of the sugar canes. The farmers will be assisted and monitored the sugar cane production to be harvested on time and deliver to the sugar mill accordingly.

All sugar mills in Thailand are not only producing sugar, but also produces its own clean energy to feed their own mills. Those mills also manage the bagasse from making the sugar to make solid fuel to produce clean electric and steam. The left over electric will be connected to the grid to sell the Electric Generation Authority of Thailand (EGAT).

Target for Five (5) Organic Sugar Mill

– Organic Sugar Mill by NSUE Mill 01 @ Udon Thani 1 Mill

– Organic Sugar Mill by NSUE Mill 02 @ Nong Bua Lumphu 1 Mill

– Organic Sugar Mill by NSUE Mill 03 @ Nakhon Ratchasima 1 Mill

– Organic Sugar Mill by NSUE Mill 04 @ Uthai Thani 1 Mill

– Organic Sugar Mill by NSUE Mill 05 @ Kanjanaburi 1 Mill

Organic Syrup Plant from Cassava

Organic Syrup Mill under the umbrella of New Era Sky United Empire Co., Ltd. (NSUE) established in 2021 which is located at Tumbol Sukasem Aumpur Pakthongchai, Nakhon Ratchasima Province is the starting the organic syrup business of NSUE with its mission to become one of the big producers and suppliers of organic syrup, Glucose Syrup, Fructos Syrup, and Sorbital to supply to local markets such as sweets, candies, toothpaste and for exports with capacity of 30,000,000 Tons by volumn ( Thirty Million Tons) per Annum.

In general, NSUE is aiming to be the center and the leader to play an important role in developing the organic syrup industry in Thailand with wide range of products including Glucose Syrup, Fructos Syrup, and Sorbitol and etc. under the brand “NSUE”. Organic materials will be used from the beginning of the cassava plantation using best soil additive biotechnology. NSUE will also promote and support the use of all organic materials, especially all types of fertilizer, to all the partners and farmers. All the production process will be at the world standard and safe for all consumers. NSUE concerns the most with health of the farmers, consumers, animals and surrounding environments (Health and Environment Concern)

NSUE concentrates on systematic cassava plantation, therefore, we useGlobal Positioning System (GPS) and Geographic Information System (GIS) to manage and improve the quality of the cassava. The farmers will be assisted and monitored the cassava production to be harvested on time and deliver to the syrup mill accordingly.

All syrup mills in Thailand are not only producing syrup, but also produces its own clean energy to feed their own mills. Those mills also manage the cassava pulp from making the syrup to make animal food and Hydrogen fuel to produce clean electric and steam. The left over electric will be connected to the grid to sell the Electric Generation Authority of Thailand (EGAT).

Target for Five (5) Organic Syrup Mill

1. Organic Syrup Mill by NSUE Mill 01 @ Sa Kaew 1 Mill

2. Organic Syrup Mill by NSUE Mill 02 @ Kampeng Petch 1 Mill

3. Organic Syrup Mill by NSUE Mill 03 @ Nakhon Ratchasima. 1 Mill

4. Organic Syrup Mill by NSUE Mill 04 @ Nakhon Sawan 1 Mill

5. Organic Syrup Mill by NSUE Mill 05 @ Kanjanaburi 1 Mill

Tapioca Starch Mill

Target for Six (6) Tapioca Starch Mill

1. Organic Tapioca Starch Mill by NSUE Mill 01 @ Sa Kaew 1 Mill

2. Organic Tapioca Starch Mill by NSUE Mill 02 @ Kampang Petch 1 Mill

3. Organic Tapioca Starch Mill by NSUE Mill 03 @ Nakhon Ratchasima 1 Mill

4. Organic Tapioca Starch Mill by NSUE Mill 04 @ Nakhon Sawan 1 Mill

5. Organic Tapioca Starch Mill by NSUE Mill 05 @ Chantaburi 1 Mill

6. Organic Tapioca Starch Mill by NSUE Mill 06 @ Nakhon Ratchasima 1 Mill

Cassava Chip Mill

Organic Cassava Chip Mill under the umbrella of New Era Sky United Empire Co., Ltd. ( NSUE )

Organic Cassava Pellet Mill under the umbrella of New Era Sky United Empire Co., Ltd. established in 2021 which is located at Tambol Sukasem Aumpur Pakthongchai, Nakhon Ratchasima Province is the starting of organic Cassava Pellet business of NSUE with its mission to become one of the big producers and suppliers of organic Cassava Pellet to supply to local markets for animal food industry. Cassava pellet has high level of carbohydrate of 65% which give energy to animals. Also, the low cost and availability of the pellets are the strong points comparing to other animal food products. Few advantages of cassava pellets are the ease of transportation and no dust during transport. The capacity is 1,500 Tons per day. Usually, 1.0 Kilograms of raw cassava will get output of 0.93 Kilogram of cassava pellets.

Organic Cassava pellet Mill

Organic Cassava Pellet Mill under the umbrella of

New Era Sky United Empire Co., Ltd. ( NSUE )

Organic Cassava ChipMill under the umbrella of New Era Sky United Empire Co., Ltd. (NSUE) established in 2021 which is located at Tumbol Sukasem Aumpur Pakthongchai, Nakhon Ratchasima Province is the starting the organic Cassava Chip business of NSUE with its mission to become one of the big producers and suppliers of organic Cassava Chip to supply to local markets such as food industry and animal food industry with capacity of 1,500 Tons ( One Thousand Five Hundred Tons) per day. Usually, 2.5 Kilograms of raw cassava will get output of 1 Kilogram of cassava chip.

Target for Six (6) Cassava pellet Mill

1. Organic Cassava Pellet Mill by NSUE Mill 01 @ Sa Kaew 1 Mill

2. Organic Cassava Pellet Mill by NSUE Mill 02 @ Kampang Petch 1 Mill

3. Organic Cassava Pellet Mill by NSUE Mill 03 @ Nakhon Ratchasima 1 Mill

4. Organic Cassava Pellet Mill by NSUE Mill 04 @ Nakhon Sawan 1 Mill

5. Organic Cassava Pellet Mill by NSUE Mill 05 @ Chantaburi 1 Mill

6. Organic Cassava Pellet Mill by NSUE Mill 06 @ Nakhon Ratchasima 1 Mill

Organic Palm Oil Factory

Organic Palm Oil Factoryunder the umbrella of New Era Sky United Empire Co., Ltd. established in 2021 to produce and sale the palm oil. Our main mission is to do the green business together with improving the living quality of the palm grower community. We aim to be one of the major players in the global market. We are not only support the farmers to grow palm trees without destroying the environment, but we also improve the method of growing palm trees by using state-of-art technology to make the best quality palm oil for all levels of consumers. The factory expects to produce palm oil with capacity of 5,000,000,000 Liters per year.

Target for Nine (9) Organic Palm Oil Factory

1. Organic Palm Oil Factory by NSUE Mill 01 @ Chonburi 1 Mill

2. Organic Palm Oil Factory by NSUE Mill 02 @ Chantaburi 1 Mill

3. Organic Palm Oil Factory by NSUE Mill 03 @ Chumphon 1 Mill

4. Organic Palm Oil Factory by NSUE Mill 04 @ Krabi 1 Mill

5. Organic Palm Oil Factory by NSUE Mill 05 @ Surat Thani 1 Mill

6. Organic Palm Oil Factory by NSUE Mill 06 @ Nakhon Sri Thammarat 1 Mill

7. Organic Palm Oil Factory by NSUE Mill 07 @ Surat Thani 1 Mill

8. Organic Palm Oil Factory by NSUE Mill 08 @ Nakhon Sri Thammarat 1 Mill

9. Organic Palm Oil Factory by NSUE Mill 09 @ Krabi 1 Mill

Rubber Glove Factory

New Era Sky United Empire Co., Ltd. established in 2021 with its purposes to manufacture and distribute the rubber gloves. We aim to be in the business with long sustainable growth together with the rubber tree farmers community. The headquarter of the factory will be located at the industrial zone in Rayong Province in Thailand. Besides Rayong factory, we also have other 5 factories spread around to produce STR20 rubber with capacity of 5,000 Metric Tons per month, natural rubber gloves with capacity of 2,000,000 boxes per day, and nitride rubber glove with capacity of 3,000,000 boxes per day. Our mission is the produce the best quality of all types of rubber gloves that make from best raw material from Southern, East, North Eastern of Thailand. Note: Thailand has the best quality of rubber in the world.

Target for Five (5) Rubber Glove Factory

1. Rubber Glove Factory (NSUE) @ Rayong 1 Factory

2. Rubber Glove Factory (NSUE) @ Nakhon Phanom 1 Factory

3. Rubber Glove Factory (NSUE) @ Chumphon 1 Factory

4. Rubber Glove Factory (NSUE) @ Nakhon Sri Thammarat 1 Factory

5. Rubber Glove Factory (NSUE) @ Patalung 1 Factory

Latex Mattress Factory

New Era Sky United Empire Co., Ltd. established in 2021 with its purposes to manufacture and distribute the latex mattress. We aim to be in the business with long sustainable growth together with the rubber tree farmers community. The headquarter of the factory will be located at the industrial zone in Nakhon Phanom Province in Thailand. Besides Nakhon Phanom factory, we also have other 3 factories spread around to produce latex mattress and pillows in all sizes with capacity of 2,000 Metric Tons per month. Our mission is the produce the best quality of all types of rubber gloves that make from best raw material from Southern, East, North Eastern of Thailand and distribute locally and globally.

Natural latex has its special characteristic such as; the texture is not too hard or too soft, latex itself naturally has high flexibility and resilient. Therefore, the latex mattress and pillow can support all level of body weights to give the best sleep quality and sleeping experiences. Another special characteristic of the latex mattress is the body weight distribution and isolation where couple can have a good night sleep without disturbance of another person if another one is moving and flipping during the sleep.

It is misunderstood that latex mattress will cause allergy symptom which is not a true statement. The latex itself has ability of anti-bacteria, fungus and bedbugs. Therefore, the latex mattress is the most suitable bed for those who have allergy.

Target for Three (3) Latex Mattress Factory

1. Latex Mattress Factory (NSUE) @ Nakhon Phanom 1 Factory

2. Latex Mattress Factory (NSUE) @ Rayong 1 Factory

3. Latex Mattress Factory (NSUE) @ Nakhon Sri Thammarat 1 Factory

Tire Factory

New Era Sky United Empire Co., Ltd. established in 2021 with its purposes to manufacture and distribute the high performance tires for personal cars, commercial trucks We aim to be in the business with long sustainable growth together with the rubber tree farmers community. The headquarter of the factory will be located at the industrial zone in Chonburi Province Thailand. Besides Chonburi factory, we also have other 4 factories spread around to produce car tires. NSUE will also invested in building “highly automated smart tire factory” with latest technology available in all 5 factories with the aim to make all types of car tires with capacity of 45 million tires per year which divide as follows :

1. High performance tire for personal cars 30 Millions / Year

2. Tire for commercial trucks 10 Millions / Year

3. Tire for agricultural trucks 5 Millions / Year

Our mission is the produce the best quality of all types of rubber gloves that make from best raw material from Southern, East, North Eastern of Thailand and distribute locally and globally under brand name “ NEW ERA” tire.

Target for Five (5) Tire Factory for “NEW ERA” TIRE BRAND

1. Tire Factory (NSUE) @ Chonburi 1 Factory

2. Tire Factory (NSUE) @ Chacheongsao 1 Factory

3. Tire Factory (NSUE) @ Samut Prakarn 1 Factory

4. Tire Factory (NSUE) @ Surat Thani 1 Factory

5. Tire Factory (NSUE) @ Nakhon Sri Thammarat 1 Factory

Agro Industrial Estate Town

39 Cities in Thailand

IMPLEMENTATION GUIDELINES

If you want to know about NSUE

How are we committed to developing living conditions and the environment to live together in the city of the future?